- Solidworks 2005 open stl how to#

- Solidworks 2005 open stl software#

The default setting is 0.0000, ignored. Vertex Spacing – This option controls the length of the edge of a facet. A setting of 0.0000 causes this option to be ignored. Surface Tolerance – This setting controls the greatest distance between the edge of a facet and the actual geometry. A setting of 1 would mean the height of a facet is no greater than its width. Aspect Ratio – This setting controls the Height/Width ratio of the facets. Reducing the angle will increase the resolution of the STL file.

Angular Tolerance – This command limits the angle between the normals of adjacent triangles.The following command line options affect the quality of the STL and should be adjusted to produce an acceptable file.Use the AMSTLOUT command to export your STL file.

Solidworks 2005 open stl software#

stl from Mechanical Desktop 3D CAD software Set absolute facet deviation to 0.000395.Select prototype device > SLA500.dat > OK.

File > Export > Rapid Prototype File > OK. dae format and use an open source software such as Blender to export that file to. Alternatively, you can export the files to. STL files without installing additional plug-ins. stl file is a fuction of the Display accuracy. You will now be able to export the CATPart in the Part Design Environment. Do NOT check: merge all bodies of each part in one body. stl files, you will have to convert the assembly in the Assembly Design environment to a CATPart as follows To export a complete assembly as a single. Additional export tolerance options are in the Solids99 Configuration window accessed from the Tolerance section of Configuration. Relocate the object to the positive X-Y-Z octant. Selected Only: Exports only objects that you selected in the 3D Studio scene. ASCII STL files are much larger than binary STL files. Binary/ASCII: Choose whether the STL output file will be binary or ASCII (character) data. Object Name: Enter a name for the object you want to save in STL format. Typically, files larger than 10MB are unnecessary and cumbersome to upload and work with. We suggest playing around with the variables of the software until satisfied with the results. However, having a low angle tolerance may alter some of the smaller features of a file. A low Standard Deviation (SD) will produce a higher resolution and larger file than will a higher SD as will angle tolerance. When choosing between ASCII and Binary, the latter is generally preferred as it will produce a smaller files size. stl viewing software such as mini magics™ to verify.

File > Export > Rapid Prototype File > OK. dae format and use an open source software such as Blender to export that file to. Alternatively, you can export the files to. STL files without installing additional plug-ins. stl file is a fuction of the Display accuracy. You will now be able to export the CATPart in the Part Design Environment. Do NOT check: merge all bodies of each part in one body. stl files, you will have to convert the assembly in the Assembly Design environment to a CATPart as follows To export a complete assembly as a single. Additional export tolerance options are in the Solids99 Configuration window accessed from the Tolerance section of Configuration. Relocate the object to the positive X-Y-Z octant. Selected Only: Exports only objects that you selected in the 3D Studio scene. ASCII STL files are much larger than binary STL files. Binary/ASCII: Choose whether the STL output file will be binary or ASCII (character) data. Object Name: Enter a name for the object you want to save in STL format. Typically, files larger than 10MB are unnecessary and cumbersome to upload and work with. We suggest playing around with the variables of the software until satisfied with the results. However, having a low angle tolerance may alter some of the smaller features of a file. A low Standard Deviation (SD) will produce a higher resolution and larger file than will a higher SD as will angle tolerance. When choosing between ASCII and Binary, the latter is generally preferred as it will produce a smaller files size. stl viewing software such as mini magics™ to verify.

Before sending any files to print, it is STRONGLY recommended to use a free. Some software may ask for inputs from users during the export process. Being relevant and up to date is important to us. We try to keep it as up to date as possible but if you notice that there is a software missing or that some of the instructions are out of date, please let us know.

Solidworks 2005 open stl how to#

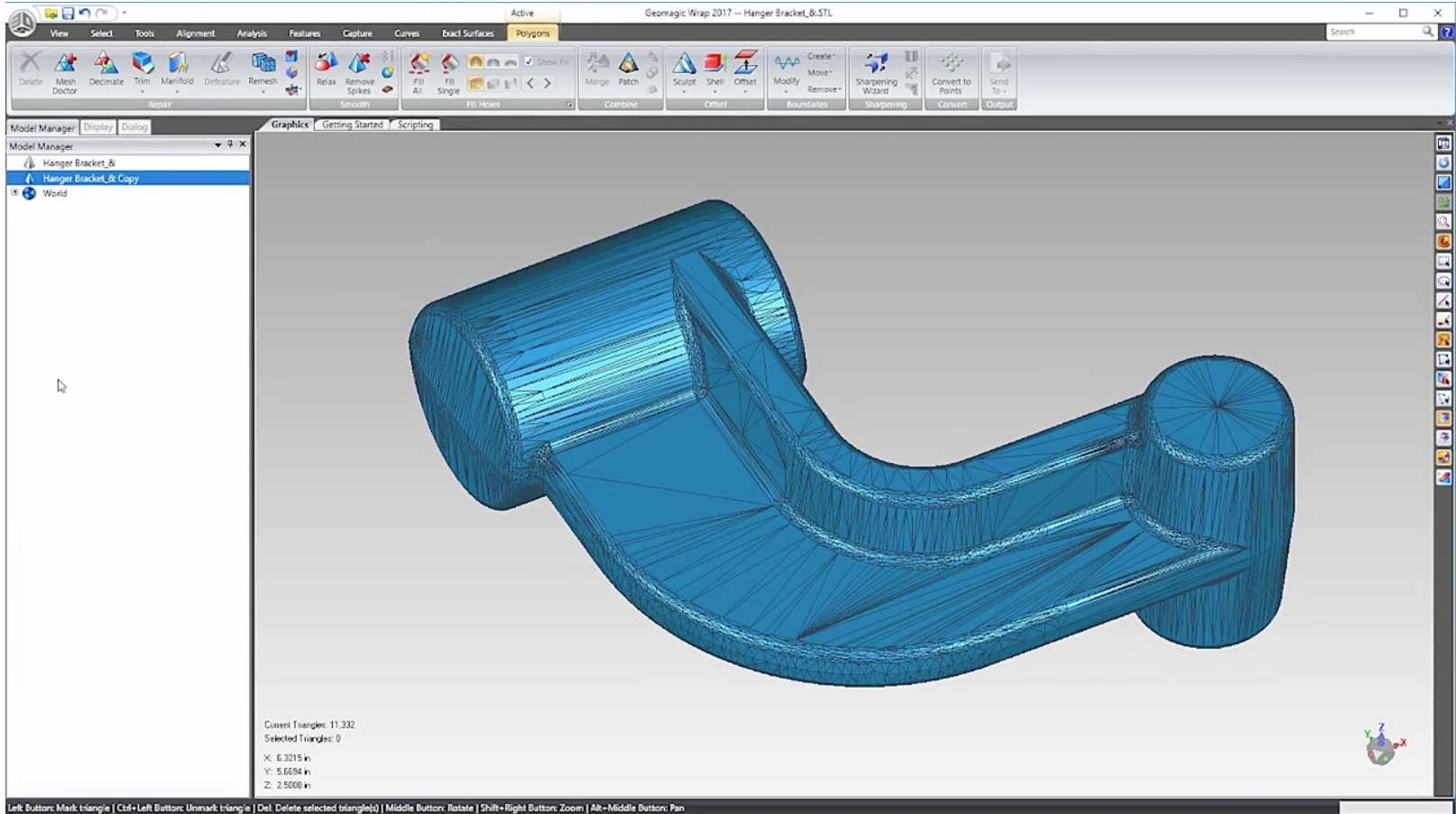

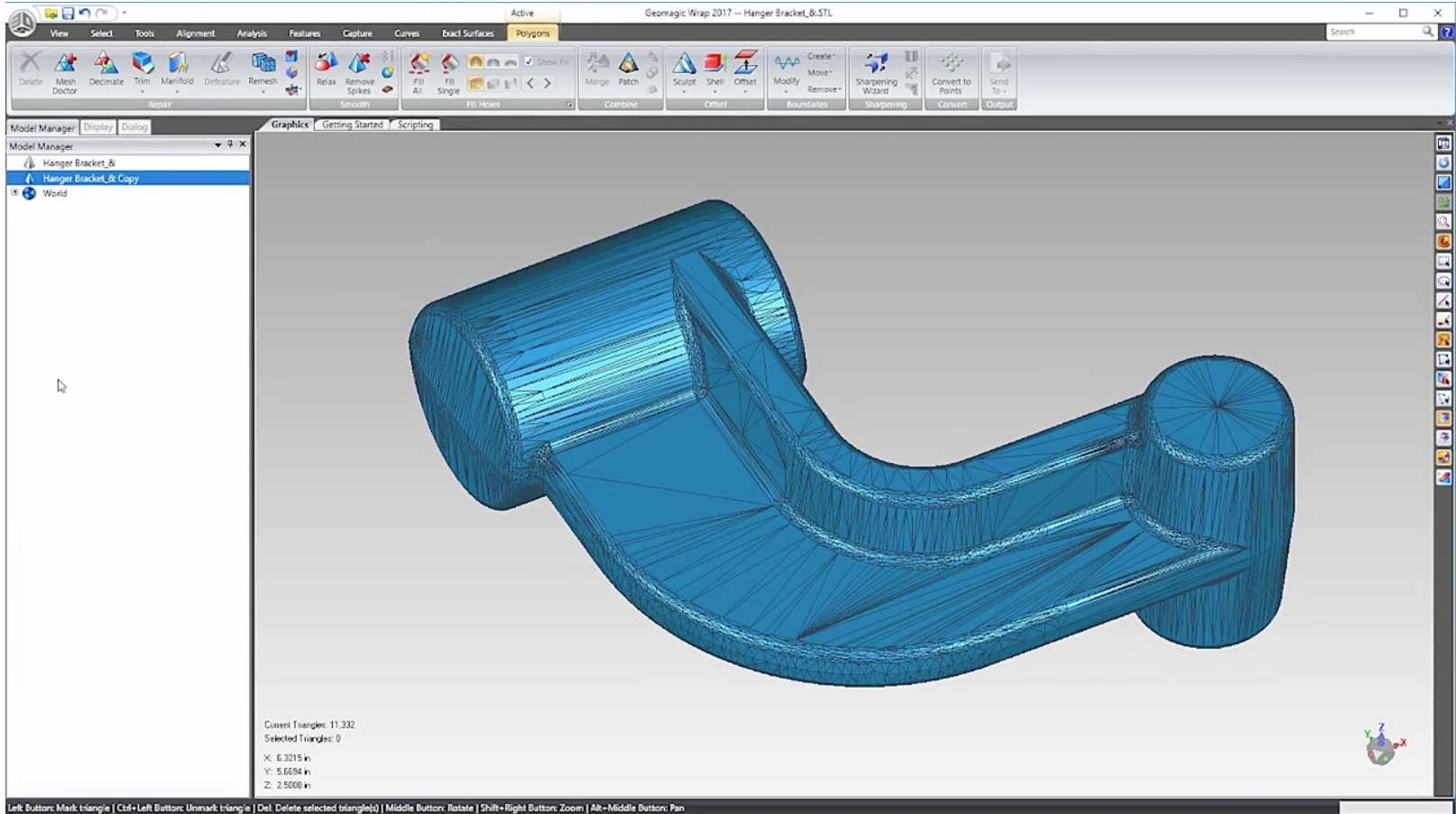

Following the steps below will guide you on how to save a file in stl format from CAD software. It lists step by step ways to export 3D Print ready files from CAD software such as Solidworks, Solid Edge, Blender, AutoCAD, and Rhino, just to name few. This is a guide to help indiviuals export stl files from various CAD software.

0 kommentar(er)

0 kommentar(er)